Nowadays, the architecture of international sports venues must not only leave unforgettable impressions on athletes and spectators on site, but also increasingly meet the interests of the media society. Creative roof constructions ensure that the worldwide television audience can take part in the game at close quarters.

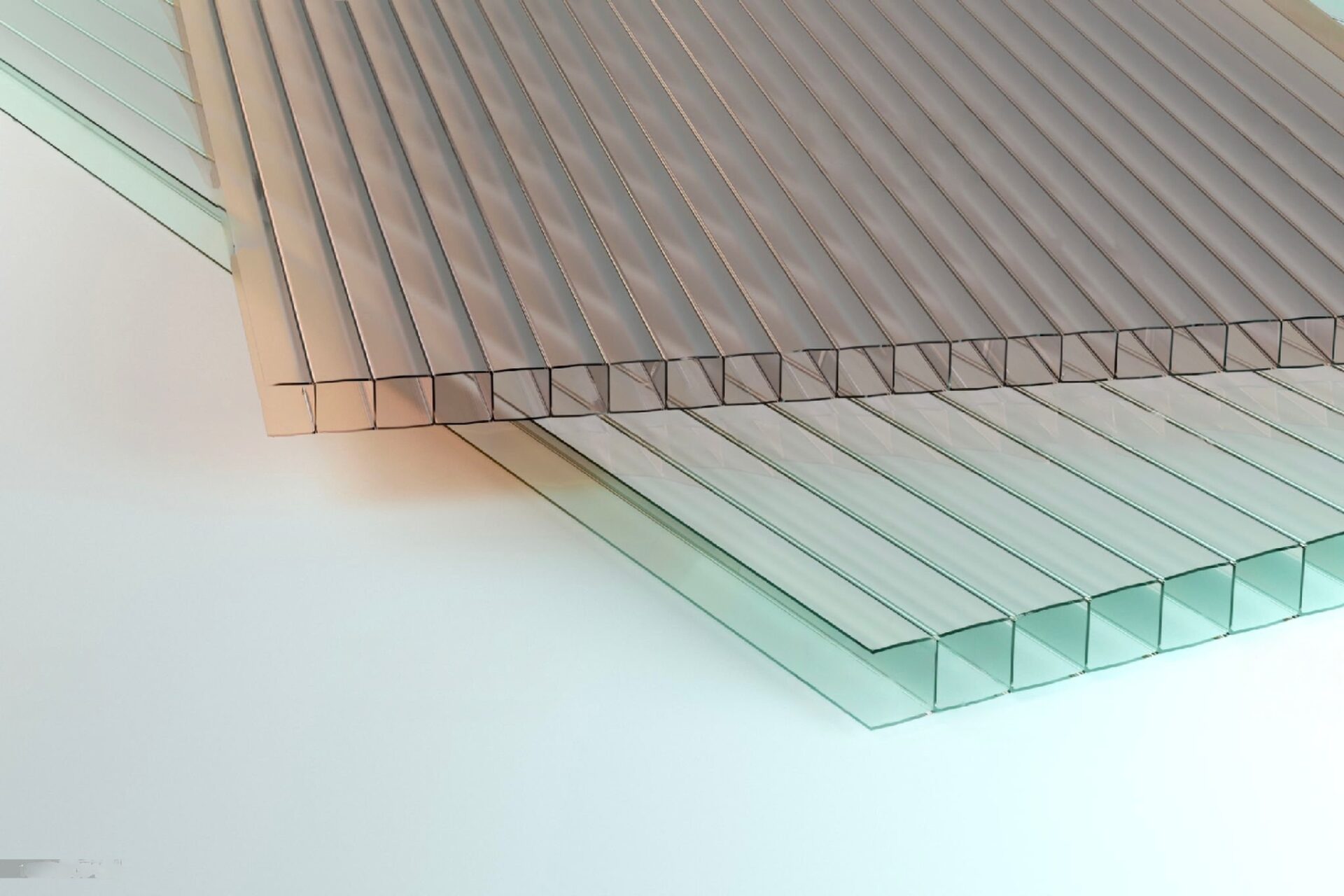

Polycarbonate sheets made from Makrolon® are particularly light and permanently weatherproof and UV-resistant. Polycarbonate can be easily processed with common tools from wood and steel construction of stadiums, polished, glued and welded without any problems. The stability of these sheets is reflected in an impact resistance that is approximately 250 times greater than float glass of the same thickness. In addition, the material polycarbonate has an Izod notched impact strength at 23 °C that is around 10 times and an elongation at break that is more than 20 times higher than that of a PMMA sheet. Furthermore, PC panels can be bent cold without any problems. The stability of the panels is also noticeable at extreme temperatures: Without additional load, the maximum service temperature is 120 °C, for a short time even 135 °C and the minimum temperature is -100 °C. Depending on the geometric design, they are flame retardant without additional flame retardants and have therefore received the fire protection class B-s1-d0 or B-s2-d0 certificate (according to EN 13501-1).

13,000 square meters of the high-tech plastic Makrolon® cover part of the stands of the sports stadium in Tianjing and form a transparent inner ring. The high light transmission of the solid Makrolon® sheets of more than 85 percent has several advantages: Since a large part of the light spectrum penetrates through the transparent roof panels, the grandstands can be pulled up far to the playing field. On the one hand, this enables a large number of seats, and on the other hand, lawn growth is not affected, since a large part of the light spectrum penetrates through the transparent roof panels. Since the Olympic football competitions were held in this stadium and the game was played on natural grass, this is not insignificant. The low specific weight of Makrolon® is also advantageous. In contrast to glass, a filigree substructure is sufficient to attach the PC panels.

The dynamic inner roof makes the Commerzbank Arena in Frankfurt the world’s largest steel-cable-membrane construction. It was designed based on the model of a lying spoked wheel, whose components hub, spokes and rim were transferred to the roof. In the center is the central node with the video cube – a 30-ton technical masterpiece. The inner pull ring on the central node corresponds to the wheel hub of the spoked wheel. 96 radial cables converge there – the spokes. The outer edge of the inner roof is the rim of the wheel and at the same time the outer pressure ring of the construction. The entire inner roof consists of a 9,000 square meter membrane. Within twenty minutes, it can be pulled together on the radial cables in the center of the video cube using sliding carriages.

The outer rim of the static roof consists of 6,000 square meters of multi-wall polycarbonate sheets. The material must meet particularly high static requirements. It must be extremely stable and at the same time highly elastic in order to be able to bear the high wind load and the movements of the roof caused by the wind even without a massive substructure. The choice fell on Makrolon® multi UV from Covestro.

Conclusion

Ecological and economical building is no longer conceivable today without plastics. Most of the advantages of transparent plastic sheets from Reform Spor lie in their contrast to glass: low weight, good formability and high light transmission, whereby not only typical building constructions, but increasingly also the multiple uses of the material – such as energy saving – come to the fore. Finally, the polycarbonate sheets can also be professionally recycled at the end of their plastic life.