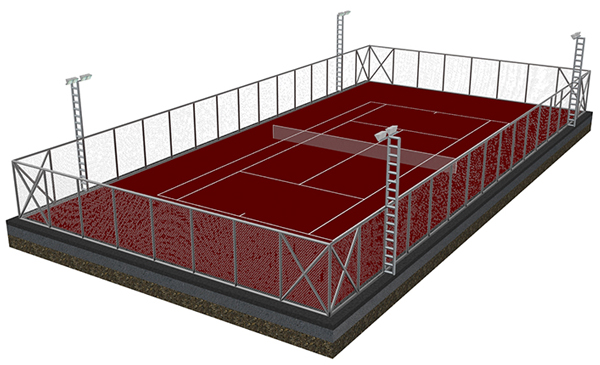

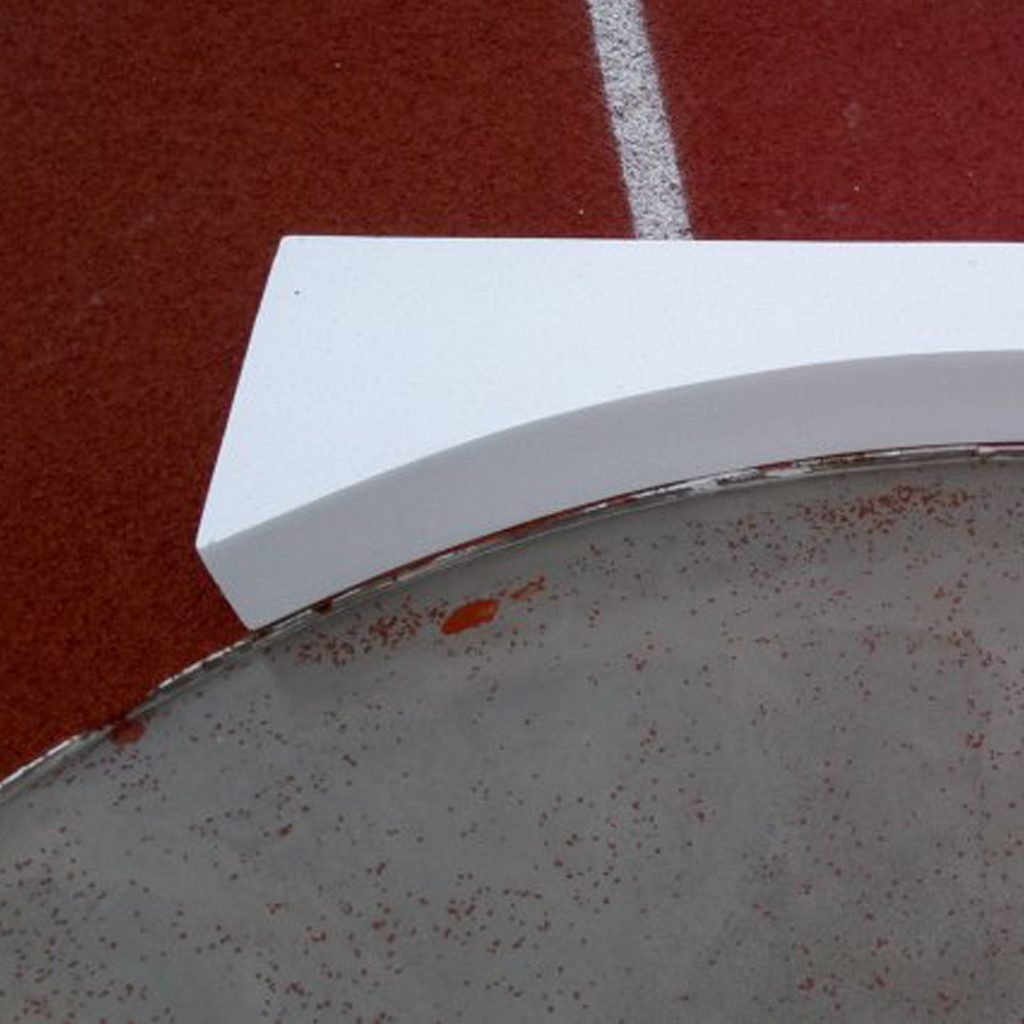

Tartan Ground Tennis Court Construction

We produce rubber in our factory in Çorlu, Tekirdağ, on an area of 12,500 m². In the rubber section which has an annual production capacity of 300.000 m²; Latest technology production techniques are used.

Tartan is made by overlapping a layer of two materials of polymer-based synthetic rubber group, referred to by SBR and EPDM abbreviations. The thickness of these layers can vary according to the demand and need. The most commonly applied thickness is 8 mm SBR + 5 mm EPDM total 13 mm. Of these synthetic rubbers applied in granules, SBR offers a flexible subfloor, while the EPDM forms a durable surface with a variety of colors.