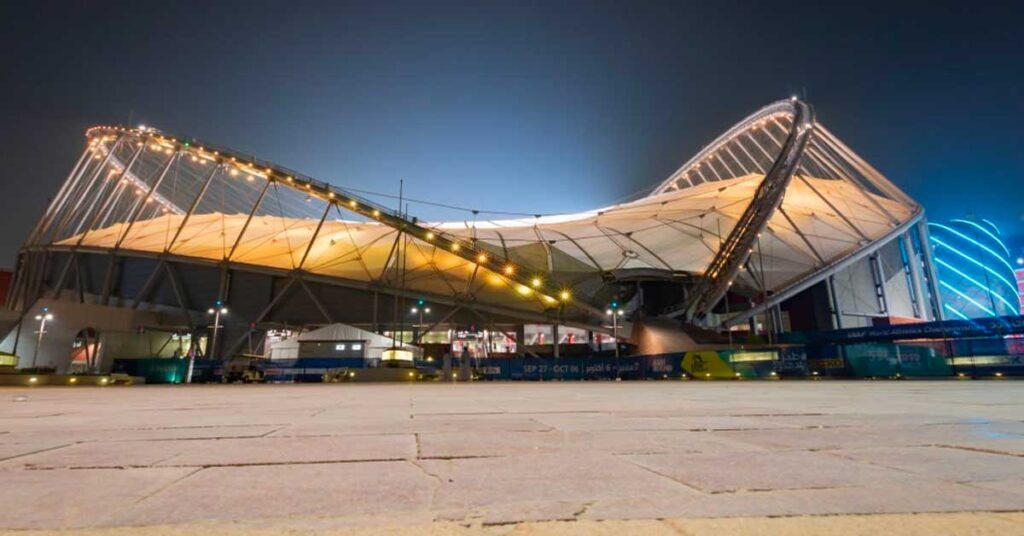

“Establishes Sports Facilities”

As Reform Group we are proud to leave 30 years of success in our journey that began in 1994. With our experienced staff, high quality products and services, we continue to grow with 6 companies and 9 brands, each of which is a leader in its own sector.

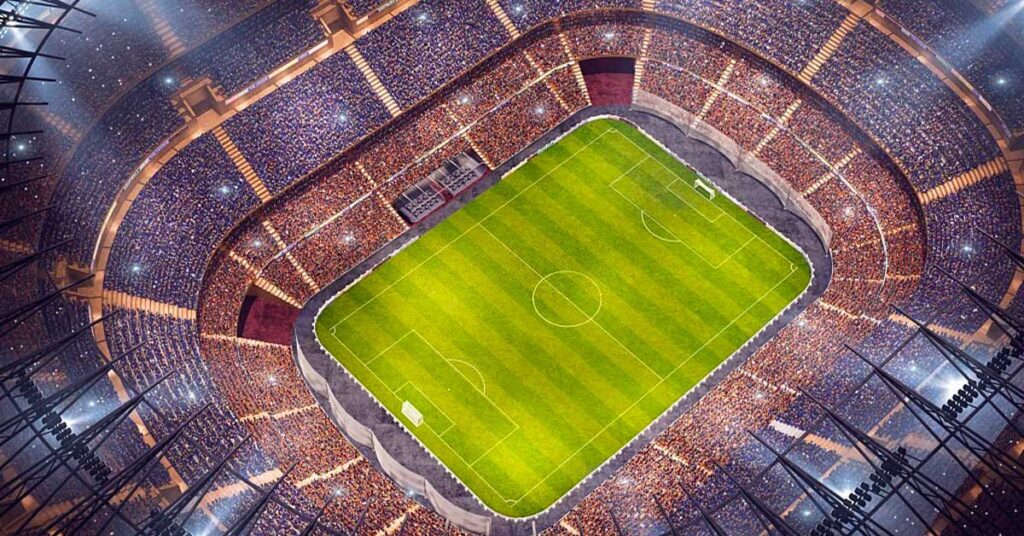

We provide durable and reliable floor solutions in international quality for all sports fields including Football Pitches Athletic Track, Basketball Court, Tennis Court, Volleyball Courts, Multi-Purpose Fields, Handball Yards Golf Courts, Hockey Courts, Baseball and Rugby Fields. We manufacture all of our products including artificial turf, decorative turf, tartan, polyurethane, acrylic, parquet and steel construction in our own factory. We have built thousands of sports facilities in our country and in the world with our expert staff from turnkey projecting to consultancy to installation and after-sales services and we continue to do so.

Reform Sports Products

We manufacture Artificial Turf, Decorative Turf, Tartan Floors, Rubber Tiles, Roll Rubber Floors, indoor and outdoor polyurethane floor coatings and acrylic floor paint under our own brand.

Reform World

You can read all the articles that we prepared related with Reform Sports company news, sectorial information and for the curiosities in this section.

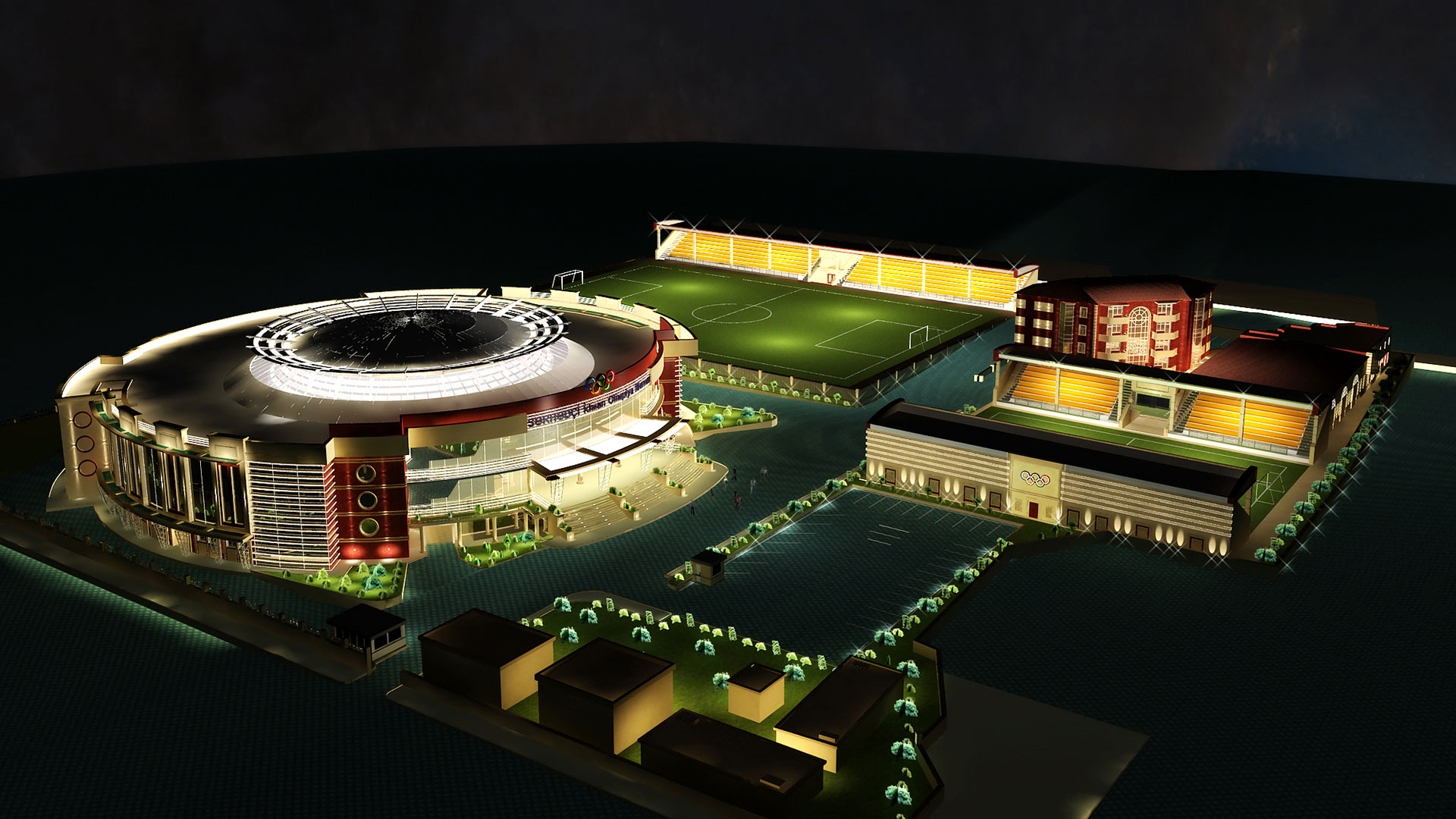

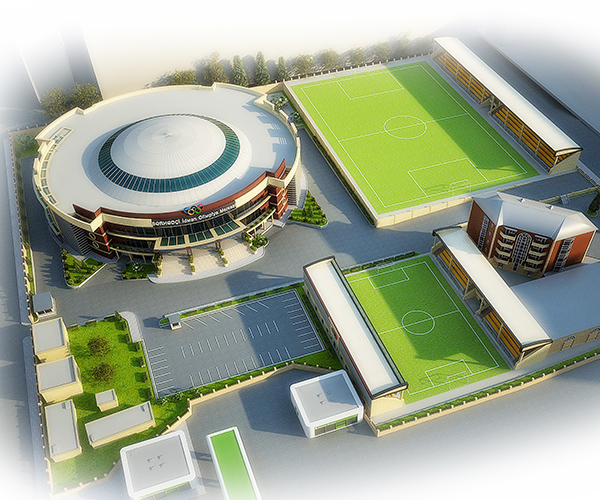

Our Projects

We have completed turn-key projects related to Outdoor Synthetic Turf Construction, Indoor Synthetic Turf Construction, Regular Football Pitch Construction, Basketball Court Construction, Multi-Purpose Field Construction, Tennis Court Construction, Athletics Track Construction and other Sports Fields Construction.